January 1, 2025 – Beijing United Coating Technology Co., Ltd. officially announced its authorization as the official agent for German IMPACT in China. This collaboration marks a significant step for both parties in the field of cold spray technology, signaling the beginning of a deeper partnership. German IMPACT, a leading manufacturer of cold spray equipment, enjoys a global reputation for its exceptional heritage and continuous technological innovation. Its flagship product, the IMPACT Evo series cold spray equipment, with a working pressure of up to 100 bar and a high-temperature processing capability of 1100 degrees Celsius, enables extremely low coating porosity and excellent bonding strength, providing high-performance surface treatment solutions for various industries.

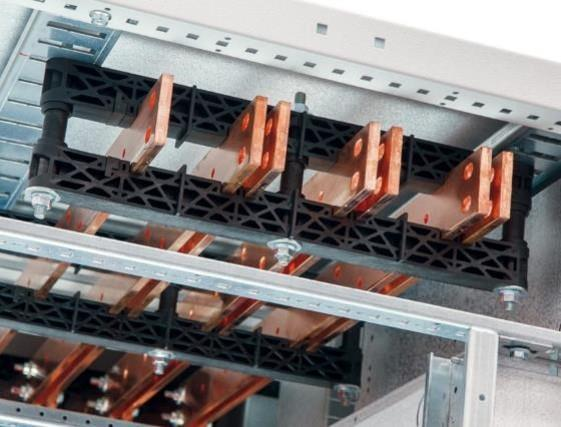

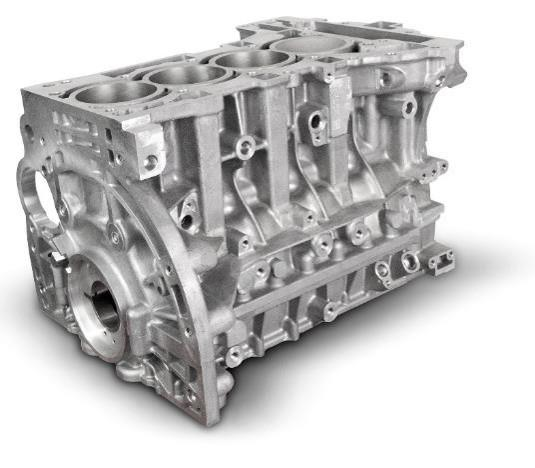

In recent years, cold spray technology, with its significant advantages of low temperature and high velocity, as well as characteristics such as low coating oxide content, minimal thermal impact, high bonding strength, and dense coatings, has demonstrated irreplaceable value in numerous high-tech fields. Whether in aerospace, semiconductors, new energy vehicles, or thermal management, vehicle braking systems, engine components, metal 3D printing, and rapid repair, cold spray technology plays a vital role. It not only enables dimensional restoration of difficult-to-weld metal parts but also provides revolutionary solutions for high-tech applications such as target material manufacturing, satellite components, power components, radar manufacturing, aircraft components, artificial implants, semiconductors, and 3D printing. Specifically, IMPACT cold spray technology has a wide range of applications, covering automotive (such as valve seats, cylinders, brakes, transmission housings, etc.), aerospace (such as turbines, combustion chambers, drive nozzles, structural components, etc.), electronics (such as heat sinks, electrical contacts, sprayed circuits, electroplating, etc.), energy (such as cookware, busbars, plain bearings, heat exchangers, etc.), engineering (such as turbines, oil and gas, nuclear energy, solar energy, etc.), and other fields, including repair, military, counterbores, corrosion protection, additive manufacturing, molds, ship components, R&D, and coating workshops.

The IMPACT Evo spraying system is designed for 24/7 operation, offering significant advantages in efficient production. It can operate 4 powder feeders in parallel and supports 2 spray guns operating in parallel for double-sided coating or increased throughput. Equipped with a rotary internal diameter coating device, it can handle fixed internal diameters greater than 70 mm and offers application-specific nozzles to optimize spraying parameters, showcasing its versatility. Simultaneously, the system is equipped with more sensors and actuators, improving process reliability, and is capable of generating and recording all process data for quality assurance and documentation. Furthermore, its open interface allows integration into higher-level controllers, and a new software architecture simplifies operation, reflecting its intelligent features, and it is compatible with all existing add-ons. More importantly, IMPACT cold spray technology itself has many advantages, including excellent heat transfer (due to the absence of oxides in the coating), excellent bonding strength (no delamination), low energy consumption (zero emissions and almost no waste), a flexible and fast process, high deposition rates and efficiency, variable coating thickness and cost control, extremely low thermal impact (no mechanical deformation), minimal porosity and uniform coating layers, significantly reduced grinding allowance, high wear and corrosion resistance, and an environmentally friendly process. These advantages collectively make the IMPACT Evo system an efficient, reliable, and high-performance cold spray solution.

The strategic alliance between Beijing United Coating Technology Co., Ltd. and German IMPACT not only signifies a deep collaboration in the field of cold spray technology but also heralds new development opportunities for the surface technology industry in China. Leveraging German IMPACT’s technological expertise in various fields, the high-performance IMPACT Evo series equipment, and Beijing United Coating’s advantages in peripheral equipment integration, automated production lines, and after-sales service, we have reason to believe that the cooperation between the two parties will bring higher-quality surface treatment solutions to the Chinese manufacturing industry, promote industrial upgrading, and jointly build a more brilliant future. We look forward to working with partners from all sectors to explore the infinite potential of cold spray technology and create a better tomorrow!