The wave of smart manufacturing is sweeping the globe, and traditional manufacturing is undergoing revolutionary changes. As a key surface treatment technology, thermal spraying also ushers in opportunities for digital, information-based, and intelligent upgrades.

Are you still struggling with the stability and efficiency of your thermal spray processes? Are you eager to get rid of tedious debugging and maintenance procedures? Do you want to improve product quality and stand out in market competition?

Today, United Coatings Company reveals the answer for you! With our rich experience, we will take you to explore the strategic significance of data acquisition and management in thermal spraying processes and share our practical experience in digital and intelligent transformation.

Data-driven, striving for excellence.

Traditional thermal spraying processes rely on manual operation, making it difficult to achieve precise control and quality assurance. Digital technology can collect and analyze key data such as spraying temperature, speed, distance, and material properties, enabling your thermal spraying process to achieve:

Process Parameter Optimization: Improve spraying efficiency, enhance coating quality, and make your products more competitive.

Quality Control: Establish a data monitoring system to monitor the spraying process in real-time, ensure stable coating quality, and completely eliminate quality problems.

Remote Monitoring: Enable remote monitoring of equipment operating status, detect problems in a timely manner, perform remote maintenance, and improve equipment utilization, making your production more convenient and worry-free.

Data empowerment: a new era for thermal spraying processes

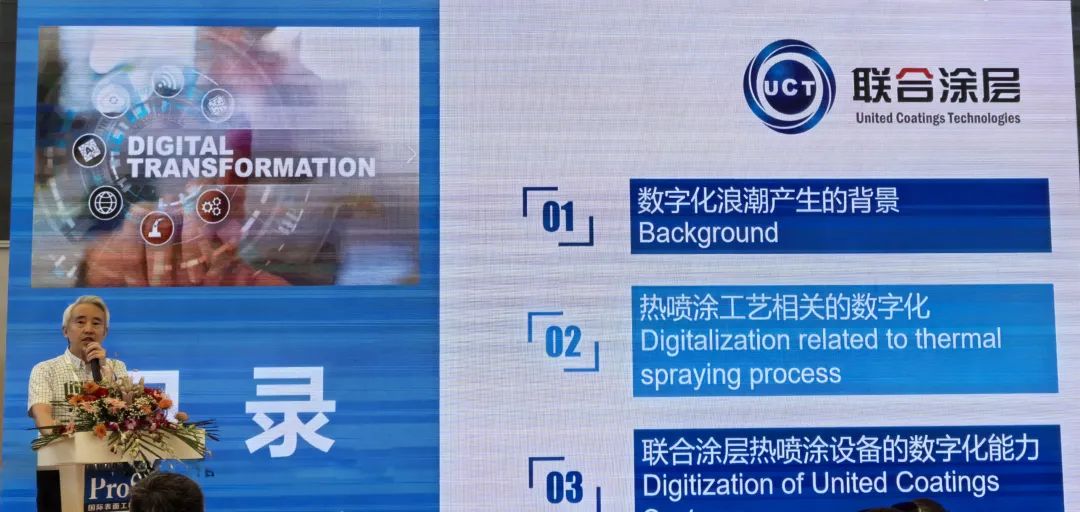

On August 8th, at the Shanghai Thermal Spray Industry Forum, Jia Peng, General Manager of United Coatings Company, delivered a brilliant speech entitled “Digitalization, Informatization, and Intelligentization of Thermal Spray Processes,” which brought the industry event to a climax. With clear logic and vivid examples, he painted a beautiful blueprint for the digital and intelligent development of thermal spray processes, igniting enthusiastic discussions and reflections on the spot. He also deeply explored the strategic significance of data acquisition and management in thermal spray processes, providing detailed explanations from the perspectives of government policy guidance and technical solutions. He emphasized that digitalization and intelligentization technologies are not only powerful tools for reducing costs and increasing efficiency, but also a key force for embracing the wave of the artificial intelligence era!

Digital transformation: Winning the future

Digital transformation is an inevitable trend for the future development of the thermal spraying industry. United Coatings Company will deeply analyze the trends and challenges of digital transformation in the thermal spraying industry and explore how to utilize digital technology to:

Establish a Digital Platform: Integrate upstream and downstream data of the industrial chain to achieve information sharing, improve collaboration efficiency, and reduce production costs.

Develop Intelligent Products: Utilize digital technology to develop intelligent thermal spray products, meet customers’ personalized needs, and enhance product competitiveness.

Build a Digital Ecosystem: Establish a digital ecosystem to connect the upstream and downstream of the industrial chain, promote the coordinated development of the industrial chain, and make your business more competitive.

Join us to:

Together open a new chapter in the intelligent upgrading of thermal spray technology,

and jointly create the future of manufacturing!