Making a Strong Appearance to Discuss the Future! United Coatings Company will showcase its leading technologies and innovative products at the 2024 International Surface Engineering Exhibition held in Shanghai from August 7-9. We sincerely invite you to visit booth A4-10 to exchange ideas, discuss the development trends of surface engineering technology, and explore new opportunities for win-win cooperation!

System Expert in Thermal Spray

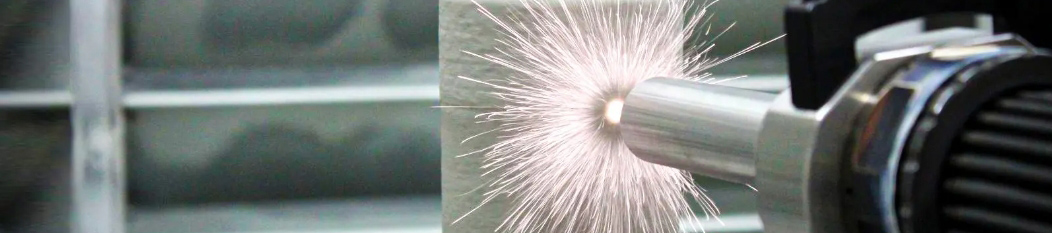

United Coatings Company has over 20 years of thermal spray experience, deeply understands industry technology, and has independently developed the high-end automated thermal spray platform UC1000 system, known for its stability, safety, and intelligent operation. The company provides comprehensive thermal spray solutions, covering flame, arc, plasma, high-velocity oxygen fuel (HVOF), detonation spraying, and cold spraying equipment, as well as peripheral equipment such as turntables, robots, and spray booths. We can also customize automated thermal spray systems according to customer needs to create a complete thermal spray processing center. Furthermore, we possess strong automation capabilities and can design the best thermal spray system equipment solutions according to customer needs, creating complete automated production lines. Our rich thermal spray practical experience and professional technology R&D team have successfully developed and applied specialized equipment to clients, including: synchronous ring molybdenum spraying automated production line, capacitor spraying special machine, etc. At the same time, the company produces various thermal spray materials and provides thermal spray processing services, providing users with fast and professional solutions.

Cold Spray Technology: Low Temperature, High Velocity, High Strength

United Coatings Company started by introducing advanced high-pressure, high-temperature cold spraying equipment from abroad. We provide customers with comprehensive cold spraying processing services, covering everything from the spraying of various metal and alloy materials to the supply of equipment spare parts and auxiliary materials. With its advantages of low temperature, high velocity, and high strength, cold spraying technology exhibits unique advantages in the field of parts repair and remanufacturing, and is widely used in many fields such as target material manufacturing, satellite components, and power components, leading thermal spray technology towards a more refined and intelligent future.

Professional Laboratory: Guaranteeing Coating Quality

United Coatings Company’s laboratory is now open to the public and offers coating performance testing services. It has complete testing equipment and professional operators who can measure the coating’s thickness, porosity, oxide content, interfacial inlay, interfacial oxide content, multiphase area, unmelted particles, microhardness, bond strength, and bending test. The laboratory strictly follows formal testing standards for inspection and is maintained and inspected regularly by designated personnel to ensure the accuracy of the test results.

Professional Thermal Spray Services: Allowing You to Focus on Your Core Business

United Coatings Company (UCT) provides customers with high-quality thermal spray services based on professional thermal spray technology and rich experience, helping them create excellent products. UCT has a professional team and advanced technology, enabling efficient and precise thermal spraying. It has developed numerous coated industrial products for various industries and achieved marketability and bulk exports. Choosing UCT allows you to avoid the burden of equipment purchase and team building, focus on your core business, and gain a competitive advantage in the market.

Coda I Data Acquisition:

Enabling Digital Management of Thermal Spraying

United Coatings Company’s Coda I software breaks through the limitations of traditional thermal spray data acquisition, enabling comprehensive data collection from core and peripheral equipment to build a complete integrated thermal spray system. The complete data collected by Coda I provides an important basis for improving production efficiency, controlling product quality, and analyzing potential problems, leading the thermal spray industry towards intelligent development. The more advanced Coda II, through the self-sensing and error correction functions of the equipment, combined with artificial intelligence technology, optimizes the spraying process, improves the intelligent level of thermal spraying, and provides customers with more efficient, reliable, and intelligent services.

United Coatings Company, as a system expert in the field of thermal spraying with over 20 years of experience, has independently developed the high-end automated thermal spray platform UC1000 system, providing customers with comprehensive solutions from equipment and materials to processing. UCT keeps pace with the times, launching Coda I and Coda II software to achieve complete collection and intelligent management of thermal spray data, leading the thermal spray industry towards intelligent development.

The Future of Thermal Spray Starts Here!

Beijing United Coatings Technology Co., Ltd. cordially invites you to visit booth A4-10 at the 2024 International Surface Engineering Exhibition to witness intelligent thermal spray solutions together and explore new opportunities for win-win cooperation!

See you there!