The 6th China International Turbomachinery Conference will grandly open in Sanya, Hainan from August 1-4, bringing together global wisdom to discuss a new chapter in the development of turbomachinery. This conference will focus on the entire chain of rotor machinery R&D, manufacturing, and application, covering frontier fields such as basic theoretical research, methodology, numerical simulation, product design, experimental research, experimental methods, and application maintenance. It will also specifically add new energy-related topics such as wind turbines, hydrogen combustion, and integrated wind-storage-hydrogen, leading the industry towards a green and low-carbon future. As an industry leader, Beijing United Coatings cordially invites you to visit our booth to exchange ideas, discuss technological innovation, and jointly plan future development.

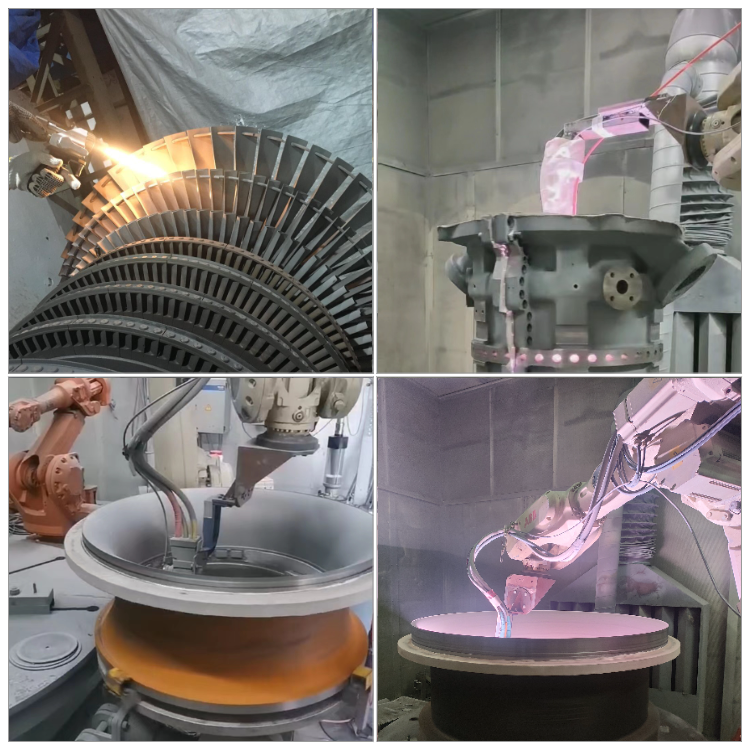

Under the guidance of the national “dual carbon” goals, the power generation equipment manufacturing sector is undergoing profound changes. Traditional coal-fired power generation equipment is transforming towards high efficiency and low emissions, while clean energy power generation technologies are flourishing, and gas turbines and turbomachinery are welcoming a golden age of development. United Coatings, as a pioneer in the Chinese thermal spray field, has always provided high-quality spraying processing services to international OEMs and domestic power plant equipment manufacturers with a meticulous attitude. We have independently developed sealing coating powders that can replace imports, helping China’s power generation equipment manufacturing industry achieve technological upgrades and independent innovation. Self-developed sealing coating materials such as LF105, LF109, and LF231 have been widely used in well-known companies such as international OEMs and domestic power plants, contributing to the green transformation of China’s power generation equipment manufacturing industry.

Abradable coatings, as a key technology for improving fluid sealing and work efficiency in mechanical equipment, play an important role in fields such as aviation, gas turbines, and industrial machinery. There are many types of abradable coating materials, each with different properties, to meet the needs of different working conditions. Nickel-aluminum composite wire, as an undercoat wire material for sealing coatings, has unique advantages in flame spraying. The nickel-aluminum composite wire (LW103) produced by United Coatings performs better than nickel-aluminum alloy wire and nickel-aluminum powder in terms of bond strength, density, and high-temperature corrosion resistance, and has advantages in construction speed and cost. It is with continuous innovation and a spirit of excellence in the field of thermal spray materials that United Coatings provides a strong support for the development of the industry and contributes to the upgrading of China’s manufacturing industry.

United Coatings, as a pioneer in the field of thermal spraying, is committed to providing high-quality spraying processing services and independently developed abradable coating materials for the power generation equipment manufacturing industry, helping China’s manufacturing industry achieve technological upgrades and independent innovation. We believe that with continuous innovation and a spirit of excellence, United Coatings will continue to contribute to the development of the industry!

You are warmly welcomed to the 6th China International Turbomachinery Conference to join United Coatings in:

Discussing a new chapter in abradable coating technology,

and jointly planning a green and low-carbon future!